This functionality allows you to assign material from one or more locations to a specialist. This, in general terms, corresponds to a transfer movement between two locations (considering the specialist as a location).

From this screen you can perform a search to list the inventory items that a specialist needs to fulfill all scheduled orders within a date range, and assign it to the specialist.

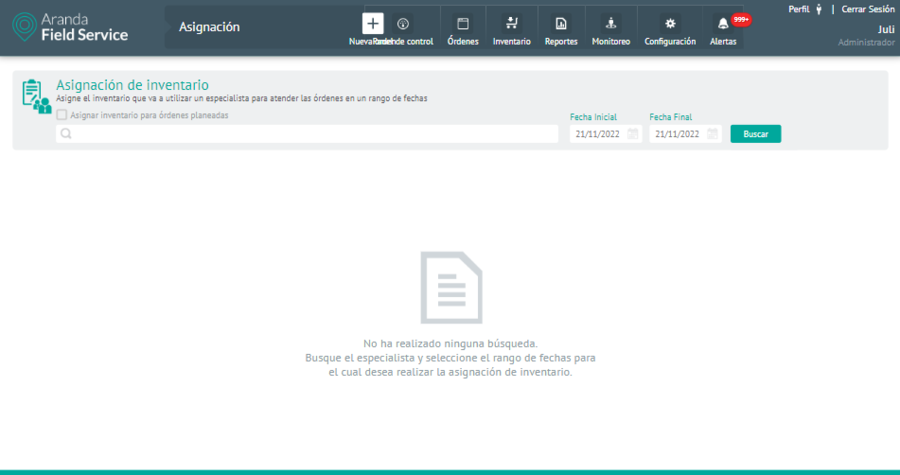

Inventory Allocation Screen

The fields to be filled out are:

- Planned Orders checkbox: Mark this box to include in the search the products corresponding to planned orders (without a fixed date of service) as opposed to scheduled orders.

- Specialist: Name of the specialist to whom you want to assign inventory.

- Start date: The date from which inventory will be assigned (the current date is displayed by default).

- End date: date until which inventory will be assigned.

Then click the To find.

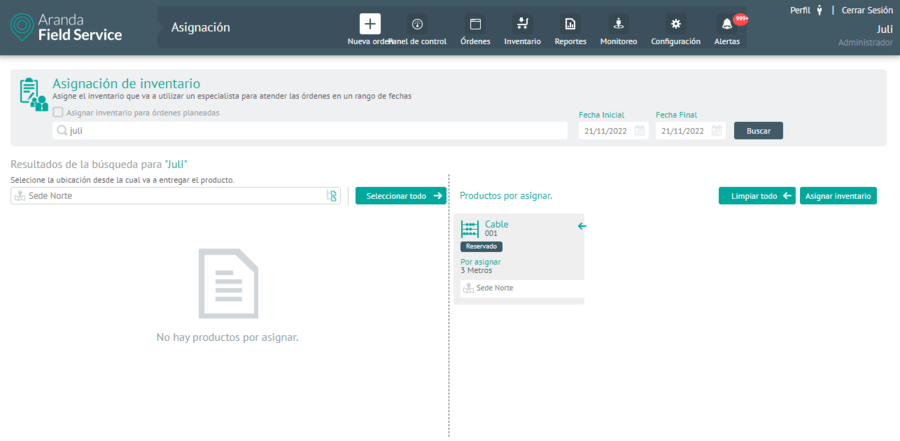

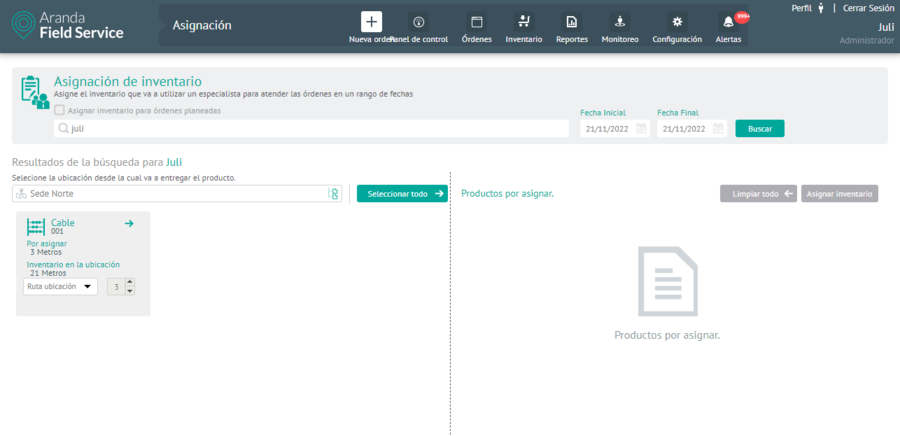

Inventory allocation example

Inventory can be reserved. That is, he has been set aside for specific orders and a specialist, all that remains is to confirm the assignment. It can also be assigned manually by selecting the location from which it is to be taken as shown below:

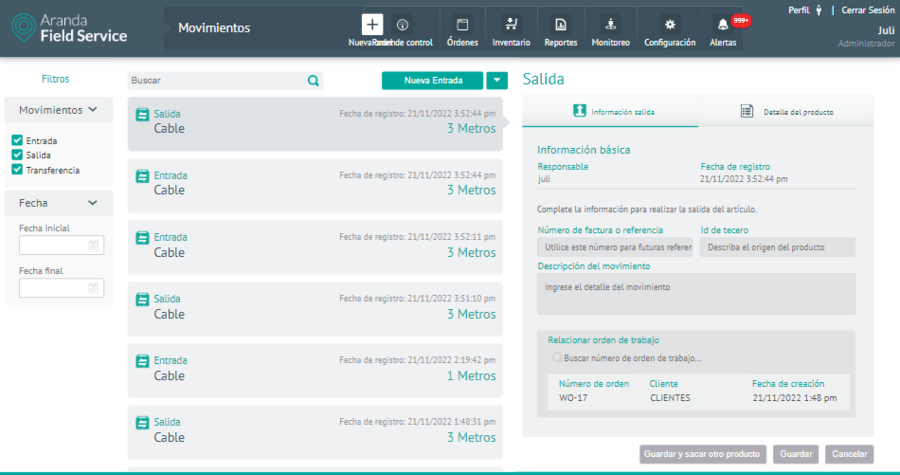

Click the Select all to make a bulk pre-selection of the products to be assigned and then click on the Assign inventory. Transfer movements will be made between the indicated parties. These movements can be confirmed by consulting the movements module.

Visualization of generated movements

⚐ Note: Inventory assignments correspond to transfer movements between a location and a specialist. Specialists are treated as a location. In this way, product transfers between locations are observed. It is not possible to create an assignment entry.